Kerby

Columbia University // Graduate School of Architecture Planning and Preservation

Professor Mark Bearak

Team: Fancheng Fei//Jasmine Ho//Jordan Meerdink//

Maximilian Hartman//Nicole Mater// Nutchanun Boontassaro//

Shalini Amin//Tanya Griffiths//Renyuan Wang

Spring 2015

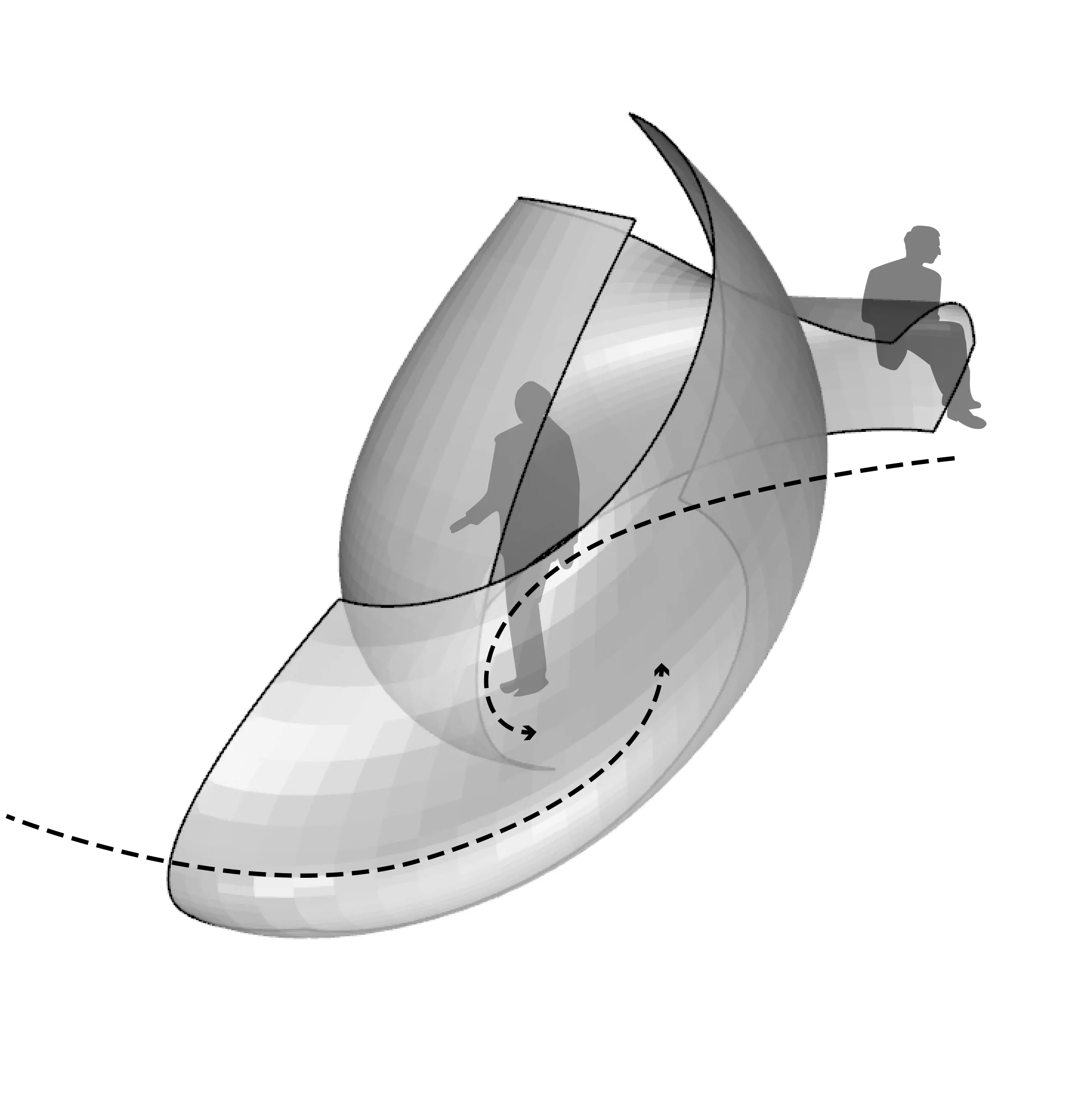

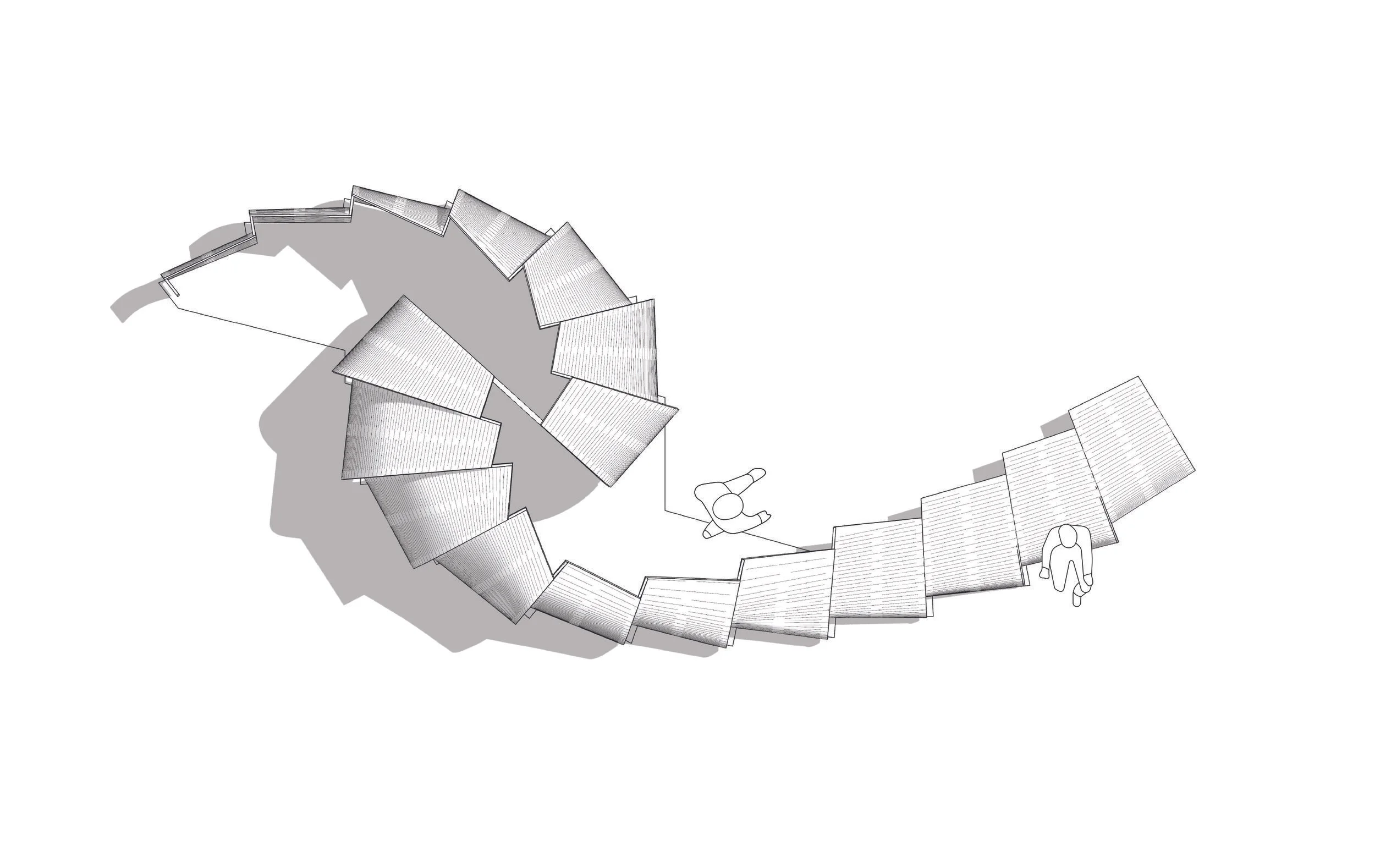

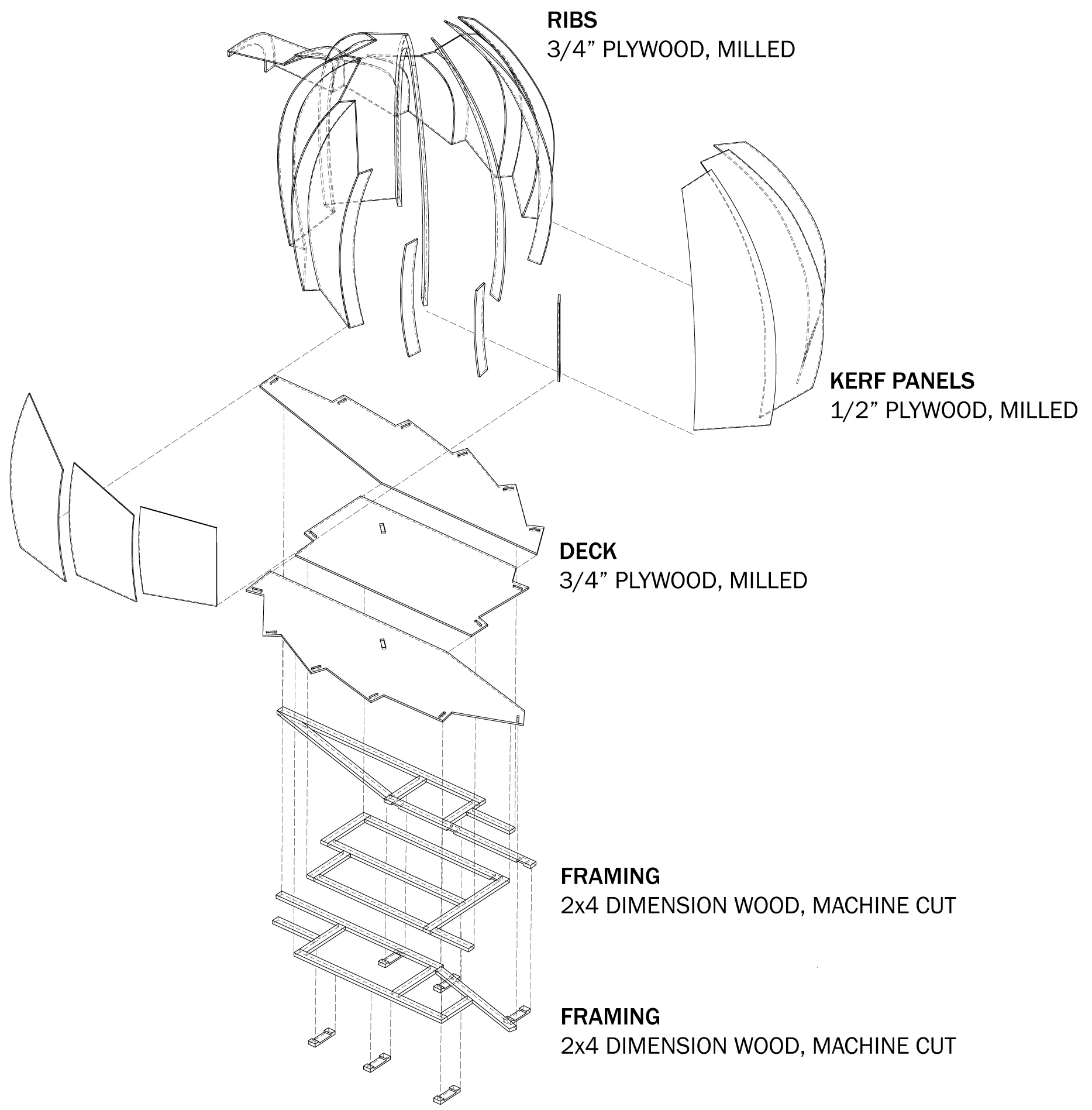

Kerby is a little monster of a pavilion. He is made of panels full of kerfs, or sninges, that allow stiff material to become flexible and curved. He was born to be a world traveler. Kerby can easily flat-pack and fit in a crate to visit cities all over the world. He is low maintenance and can be re-built quickly, like a big 3D puzzle.

What's in a Kerf?

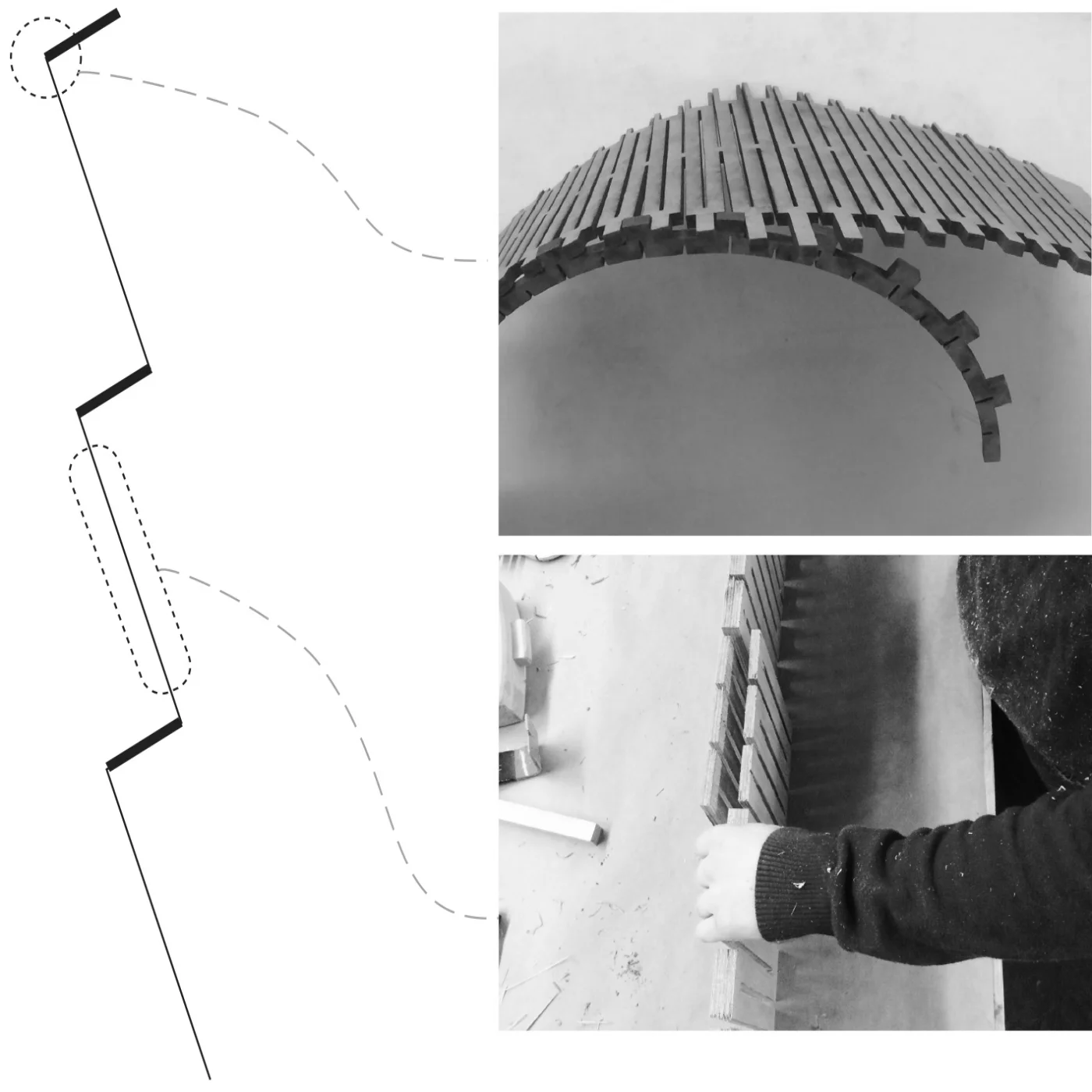

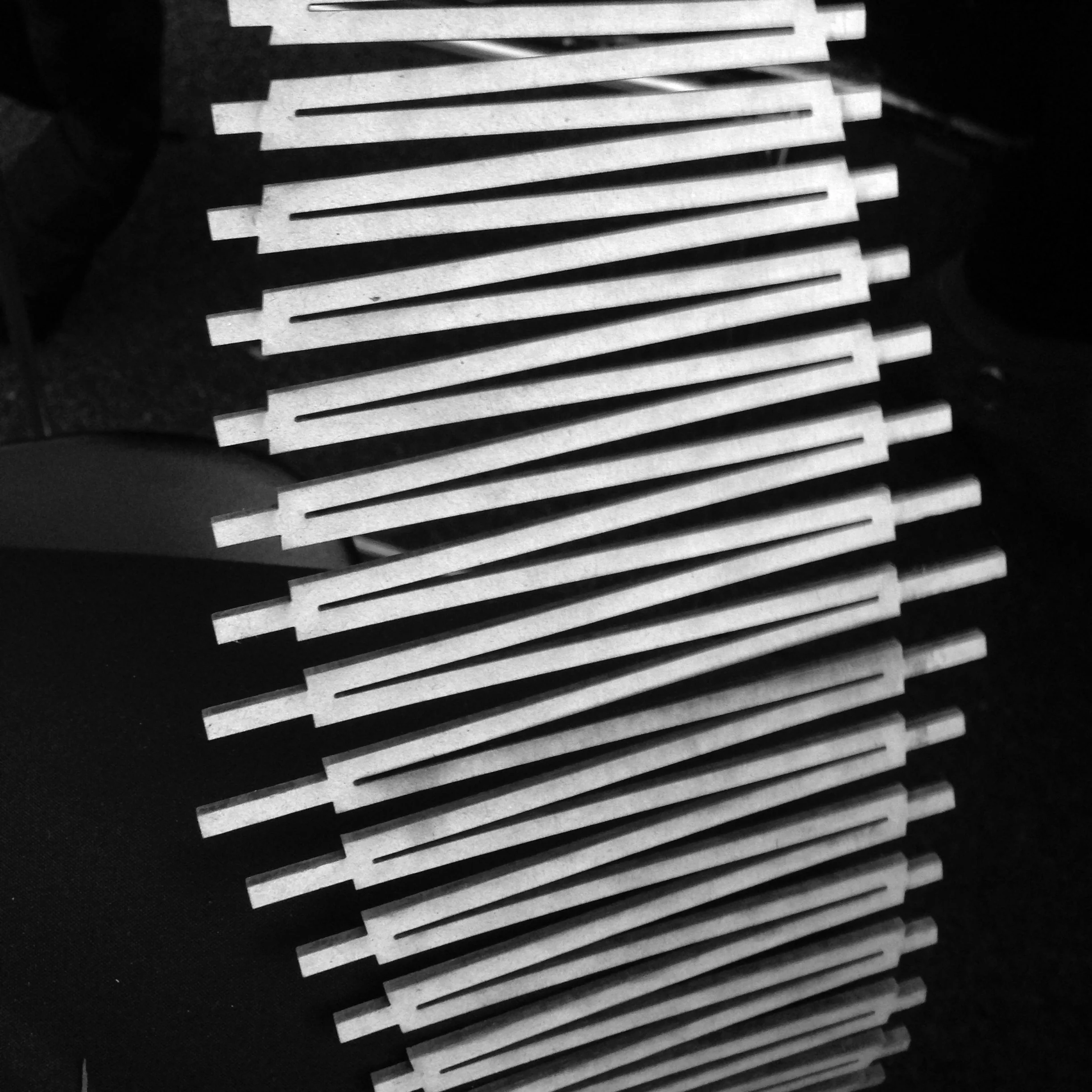

Several different styles of kerf were cut on 3/4” shop grade plywood to find the one with appropriate bending rate and stiffness.

Finding Form

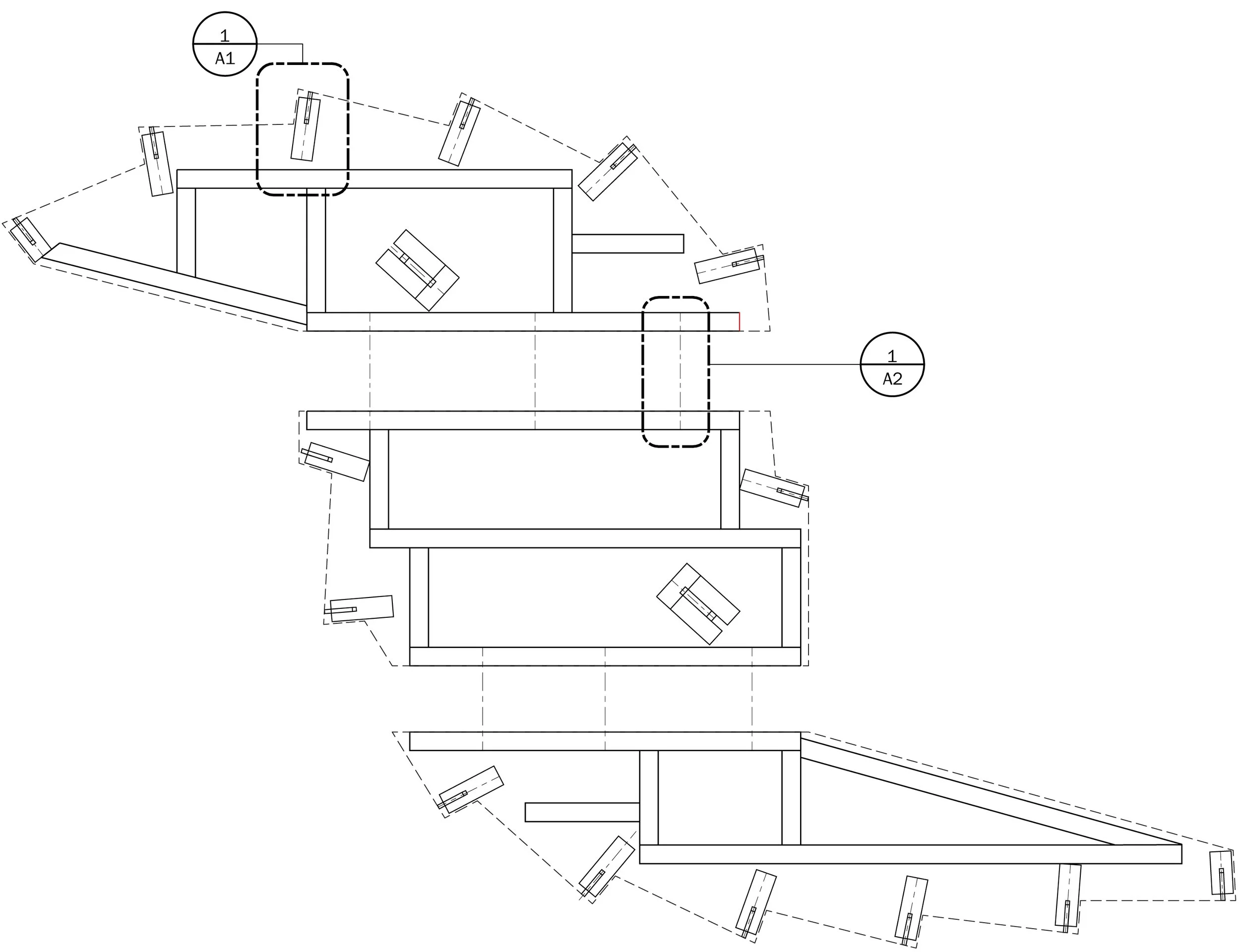

Through a series of study models the design became a series of repeatable movable parts. Ultimately, Kerby would be two interlocking shellscomprised of these parts. Their embrace generates a path

Responsive Design

Scripting computer software allowed for a system of predictable Kerfs that would manipulate the panels to produce the correct bends to render the desirable form.

Some Assembly Required

A clear and easy method of construction allows Kerby to be shipped any where and be constructed by anyone.

Its in the Details

A perfect marriage of rigid connections and flexible parts creates a fluid and beautiful structure.